Rick Smith, the founder of the Global Coalition on Additive Manufacturing (GCAM), believes that 3D printing is about to disrupt your industry. In an article for Forbes magazine, the co-founder of CloudDDM claims that industrial 3DP “has reached its tipping point and is about to go mainstream.” Smith then explains why technologies that were once limited to prototyping are now revolutionizing full-scale production.

Prototyping and design iterations are still important, of course, but recent advances in automation have made 3DP truly rapid for the first time. Meanwhile, improvements in quality have blurred the line between prototypes and first-run production parts. 3D printing also supports cost-effective, low-volume production. There are no tools to build nor molds to make, and the setup costs are the same (none) regardless of quantity.

Industrial 3D printing also support what Smith calls “mass customization”, a trend that’s already revolutionizing medical manufacturing. From artificial knee replacements to teeth alignment devices, industrial 3DP supports one-of-a-kind modifications to items that are produced in large quantities. Additive manufacturing also supports a “virtual inventory” of spare parts that companies can create on-demand.

When an assembly or asset becomes obsolete, 3D printing also offers what Smith calls “a long tail” of replacement parts. Older, but still-useful products can then remain in the field instead of the scrap yard. At the same time, industrial 3DP promotes product innovation by lowering the barriers that manufacturers face from design and prototyping through production and inventory control.

“We find ourselves at a key inflection point in history,” Smith concludes, “but the current uses for 3D printing in production are what email was to the Internet in 1994: an example of the incredible utility of a new technology, but also, merely a glimpse of the sweeping changes to come.” Do you agree with his analogy?

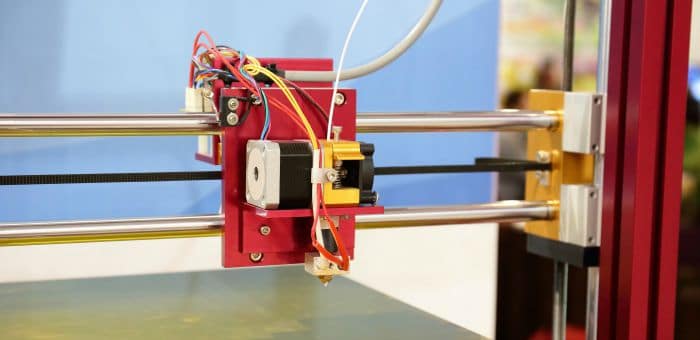

Image Credit: © ryanking999/Dollar Photo Club