3D printing isn’t just for prototyping. Additive manufacturing supports product design and development, but companies can also realize cost-savings on production runs. Moreover, 3DP is capable of creating parts in in almost any shape or size. Eliminating geometric constraints is powerful, but is it enough to convince industry that 3D printing is the way to go? For manufacturers, there are five areas to address.

First, define your scope. Do you want to use 3D printing just for prototyping, or would you like to explore additive manufacturing for production? Second, get specific. If you want to put 3D printers on the shop floor, how will you qualify parts for customers? Third, set your speed. If your company’s goal is to go quickly, then it’s time to think about partnerships with providers and how to hire trained personnel.

All three areas are inter-related, but they also fit in with the fourth and fifth factors you’ll need to consider. What level of integration do you expect from your value chain, and how will your business realign its organizational structure? Additive manufacturing offers flexibility and control, but you’ll need to balance these benefits against all of your costs.

In terms of integration, manufacturers need to make decisions about everything from design software to final parts testing and repair. Which activities will your company perform in-house, and is vertical integration the ultimate goal? In terms of organizational structure, production planning and engineering need to be ready to play a larger role. How will this change affect interactions with operations and quality assurance?

Companies across New York State are using additive manufacturing for more than just prototyping. By understanding all of the areas that they need to address, manufacturers can implement 3D printing effectively, efficiently, and with both short-term and long-term goals in mind.

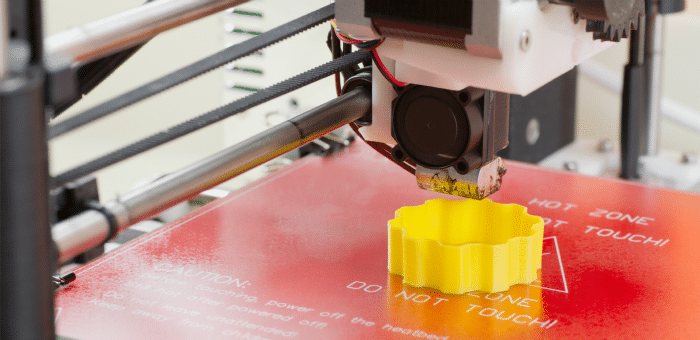

Image Credit: © hopsalka/Dollar Photo Club