In the heart of Silver Creek, NY, a revolution in industrial processing equipment was brewing. S. Howes, a company with deep roots in manufacturing, was about to embark on a journey that would not only transform their business but also set new standards for environmental responsibility in their industry.

The challenge was clear: traditional direct heat-transfer equipment, while efficient, was plagued by uneven heating and high emissions. As industries across the board faced increasing pressure to reduce their environmental footprint, S. Howes saw an opportunity to lead the charge.

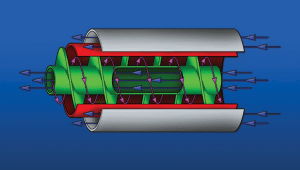

Enter the next-generation thermal screw conveyor – a game-changing technology that promised to deliver precise heating and cooling while minimizing emissions. But bringing this innovation to market would require more than just engineering prowess. It would take a village, or in this case, a university.

The Power of Partnership

S. Howes found their perfect collaborator in the University at Buffalo’s Center of Excellence in Materials Informatics (CMI). This partnership opened doors to a wealth of resources:

- Cutting-edge research expertise

- Access to bright, young talent

- High-performance computing capabilities

- Crucial funding opportunities

With these tools at their disposal, S. Howes set out to design, manufacture, and prototype their revolutionary equipment.

From Concept to Reality

The journey from idea to marketable product is often fraught with challenges, but S. Howes had an ace up their sleeve. A FuzeHub Manufacturing Grant, secured through their partnership with CMI and UB’s Department of Chemical and Biological Engineering, provided the financial boost needed to refine and test their equipment.

UB’s Business and Entrepreneur Partnerships stepped in, offering advanced manufacturing experts, student talent, and state-of-the-art facilities. This collaboration was the catalyst in which S. Howes’ prototype was forged and perfected.

The Fruits of Innovation

The result? A high-efficiency, environmentally friendly thermal screw conveyor that not only met but exceeded industry expectations. This equipment offered precise and efficient heating or cooling through indirect heat transfer, a significant leap forward from traditional methods.

But the true measure of success in business is sales, and S. Howes’ innovation delivered in spades. In the fiscal year 2021-2022, the company saw $1.5 million in sales. But that was just the beginning. The following year, from July 2022 to June 2023, sales skyrocketed to $8 million – a testament to the market’s hunger for sustainable solutions.

A New Chapter in Manufacturing

As we look to the future, the story of S. Howes serves as a powerful reminder of what can be achieved when innovation meets collaboration. By partnering with academic institutions and leveraging available resources, even long-established companies can pivot, innovate, and lead in the face of new challenges.

In the end, this isn’t just a story about a new piece of equipment. It’s a story about reimagining what’s possible, about finding new ways to meet old needs, and about the power of partnerships to drive progress. As industries worldwide grapple with the dual demands of efficiency and sustainability, the path blazed by S. Howes and the University at Buffalo offers a blueprint for success.