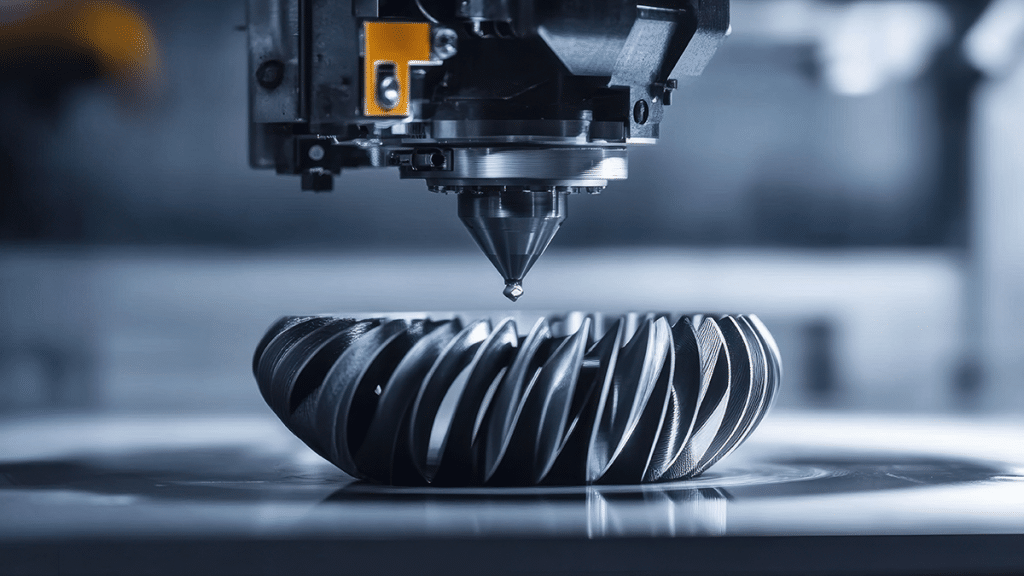

NIST researchers, as featured by public affairs specialist Brian Gutierrez, are pioneering a novel approach to improving the reliability of metal 3D printing by analyzing laser light reflections—known as caustics—during the printing process. Gutierrez, who covers advancements in energy, climate, building science, and manufacturing, highlights how these optical patterns—familiar from everyday phenomena like light dancing on pool water—can provide real-time insight into the microscopic shape of molten metal as it’s fused layer by layer.

By studying caustic reflections, scientists aim to detect and address printing defects—including the elusive “keyhole pores” that can compromise part quality—which occur rapidly and in visually inaccessible conditions. Custom equipment, such as reflective domes and high-speed cameras, enables observations inside the intense environment of industrial 3D printers. These innovations open the door to real-time process control, allowing for more consistent and higher-quality printed metal parts.

While the technology remains experimental and isn’t ready for widespread commercial use, Gutierrez emphasizes that this foundational research points toward new monitoring tools that could bring metal 3D printing within reach for more companies, including small manufacturers and innovative startups.

For the full article, visit the NIST website.