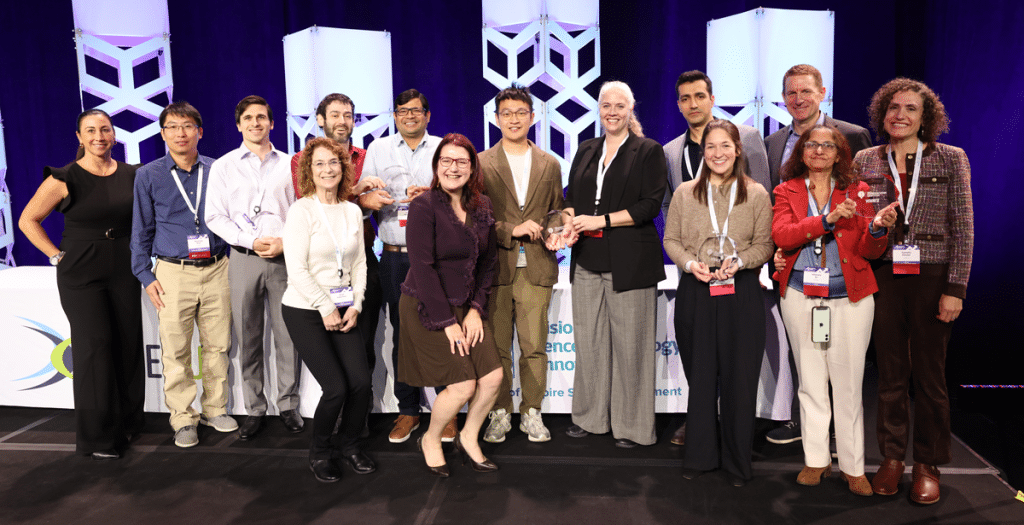

(Albany, NY – October 31, 2025)—FuzeHub is excited to announce the winners of its ninth 2025 Commercialization Competition. This Competition occurs yearly as part of the Empire State Development-supported FuzeHub Jeff Lawrence Innovation Fund, and increased award amounts were made possible by additional funding from NYS Governor Kathy Hochul’s office. Twelve entrepreneurs from across the State competed for a chance to win one of four awards. The grand prize-winning company took home $150,000; the runner-up secured $100,000, one team received $80,000, and two more teams received $60,000 each toward their startups.

“We’re proud to celebrate this year’s Commercialization Competition winners. Their projects reflect the incredible ability of New York State’s innovation ecosystem to solve problems through technology and ingenuity,” said Ben Verschueren, Executive Director of Empire State Development’s Division of Science, Technology and Innovation (NYSTAR). “By pairing visionary entrepreneurs with targeted support through the Jeff Lawrence Innovation Fund, we’re not just recognizing commercialization potential—we’re investing in the future of our state’s economy.”

“As New York continues to invest in technology innovation, FuzeHub is honored to help entrepreneurs move their creative ideas onto successful products,” said Patty Rechberger, Innovation Fund Manager at FuzeHub. “This year’s competition drew inspiring talent from across the state, and this funding helps accelerate their journey from concept to commercialization. We’re excited to support their growth and follow the positive impact they bring to the world.”

The first-place team and the winner of the $150,000 grand prize is REEgen (Southern Tier)

BioREEcovery Scale Up

REEgen is transforming the way the world gets its critical minerals—the lesser-known metals that drive modern life. In particular, REEgen is focused on recovering rare earth elements (REEs), which are essential for making strong, lightweight magnets that power everything from electronics, your car’s power steering system, to wind turbines. Currently only 1% of REEs are recycled today and the global supply chain is dominated by China, making the production of these critical minerals a national security priority in the U.S. Using what already exists in nature, REEgen has genetically engineered a new approach for recovering and purifying these metals from industrial waste, making their production cleaner, safer, and more efficient. Through this approach, REEgen aims to create a circular and secure economy for rare earth and critical metal production in the United States.

The runner-up team was awarded $100,000: GynStrong, Inc. (Mid-Hudson)

Tamicap: A Pelvic Pain Relief Device

One in three women suffers from debilitating pelvic pain caused by menstruation, endometriosis, or adenomyosis—which costs the US economy $4.9B dollars annually in loss of productivity and in health care costs. GynStrong is on a mission to end that pain with the world’s first intravaginal device that uses electrical pulses to provide targeted pain relief and menstrual collection in one discreet, app-connected product. Developed by Dr. Tamatha Fenster of Weill Cornell Medicine, who realized that better solutions were needed for her patients. Tamicap offers a safe, effective, non-surgical, and drug-free alternative that can be used anywhere. Through a mobile app, users can personalize and control their level of pain relief for a truly tailored experience. Tamicap represents a groundbreaking advancement in women’s health—merging innovation, empathy, and science to finally address a long-neglected need.

One team was awarded $80,000: CryoBio, Inc. (Southern Tier)

An affordable and effective solution to fight frost in agriculture

New York farmers are facing major increases in frost damage over the last 10 years, with some losing about 90% of their crops to a late frost in 2023, pushing many to the verge of bankruptcy. This is not just a local issue; it is a growing global disaster that is worsening due to unpredictable weather patterns, destroying up to 5% of the world’s food supply each year, enough lost food to feed 200 million people. CryoBio is developing a one-of-a-kind spray solution that prevents ice formation on crops to eliminate frost damage. Founded by a Cornell researcher and serial entrepreneur who grew up on a rural farm, CryoBio’s mission is urgent and personal; they have seen the devastating effects of extreme weather firsthand. The successful development of this technology will save tens of millions of dollars for NY farmers and provide the only affordable and effective solution for about 95% of affected growers worldwide.

In addition, two additional teams will receive $60,000 each toward their startup ventures. This includes:

IVSonance Biomedical Inc. (Southern Tier)

IVSonance: Hands-Free Acoustic Automation of IVF Within Everyone’s Reach

The field of in-vitro fertilization (IVF) is at a crossroads: demand for fertility care is growing rapidly, yet access remains limited because many core procedures still rely on manual precision and labor-intensive techniques that are difficult to scale. Before eggs can be fertilized, embryologists must carefully remove surrounding protective cells, a delicate, time-consuming process that requires specialized expertise and limits how many patients a clinic can serve. IVSonance, developed at Cornell University and Weill Cornell Medicine, addresses this challenge with a transformative acoustic technology built on the powerful principle of moving objects without touching them. Using gentle sound waves to create precise microscopic currents, IVSonance separates ancillary cells from eggs with greater consistency and speed than manual techniques allow. By automating this labor-intensive step, the technology enables clinics to expand capacity while maintaining precision and safety, helping to make fertility treatment more accessible and scalable for the growing number of hopeful parents seeking to build their families.

TunaBotics LLC (Central New York)

Soft Shell Grippers to Accelerate Automation in Advanced Manufacturing

TunaBotics develops robotic grippers made of soft materials that let robots pick up objects that are too small, delicate, or curved for existing tools. Each gripper is soft and shaped like a hollow half-ball that adjusts to every object it grips, holding it securely without damage. The grippers can stick to objects when needed and unstick on demand, controlled by air pressure to allow a firm hold or an easy release. Because the grippers do not require bulky vacuum pumps, they are lightweight, energy-efficient, and easy to integrate into many types of systems. This makes them especially valuable in electronics assembly, where people still handle many components by hand, and opens opportunities in other settings such as farms, hospitals, and homes. TunaBotics’ grippers free humans from tedious, repetitive tasks—from assembling electronics to picking fruit and mushrooms—and even enable gentle robotic healthcare, such as assisting patients with eating and other daily activities. TunaBotics’ soft gripper technology can bring safer, more reliable automation to a wide range of industries, helping improve efficiency, reduce strain on workers, and expand what robots can do.

The New York State Innovation Summit celebrates New York State leadership in technology-led economic growth. Companies and researchers at the forefront of emerging technologies and new advancements in production capabilities were showcased while current technology convergence opportunities, ways to accelerate commercialization, and issues of manufacturing sustainability were explored.

During the Summit, finalists demonstrated the commercialization potential of their product or technology and competed against each other for one out of five awards. Award funds must be used to improve an existing prototype, enabling the company to pursue additional investments and customers, and leading to the commercialization of their product.

About Jeff Lawrence

During his more than 20 years at the Center for Economic Growth, the Manufacturing Extension Partnership (MEP) affiliate in the Capital Region where he served as executive vice-president and MEP center director, Jeff Lawrence directed programs of direct assistance to manufacturers and technology companies to increase their competitiveness. He is remembered for being an invaluable and generous mentor to many in the area’s business community and a tireless advocate for manufacturing innovation throughout New York.