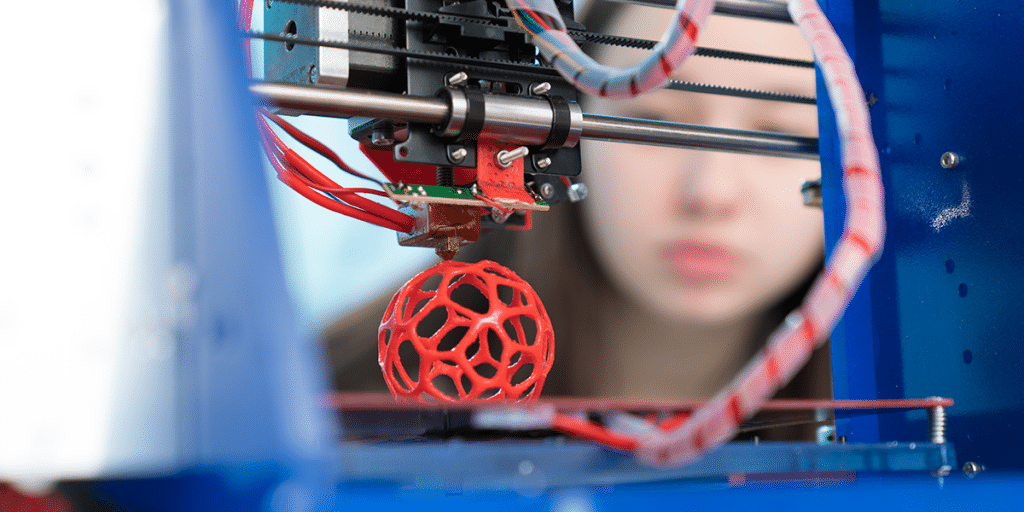

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes, where an object is created by laying down successive layers of material until the object is formed. It is possible to use different substances for layering material, including metal powder, polymer, ceramic, composites, and biologics.

Recent years have brought incredible growth and adoption of additive manufacturing technologies in consumer products and manufacturing environments. The primary applications of additive manufacturing are design/modeling, fit and function prototyping, and direct part production. The adoption of additive manufacturing technologies is changing the way organizations design, manufacture, and source components. When used correctly, additive manufacturing can save time and money throughout the product lifecycle, impacting design, prototyping, and manufacturing efficiency while avoiding costly errors and enhancing product quality. A wide and diverse range of materials, processes, and equipment, along with service providers, provide even small companies the chance to explore new opportunities for improvement.